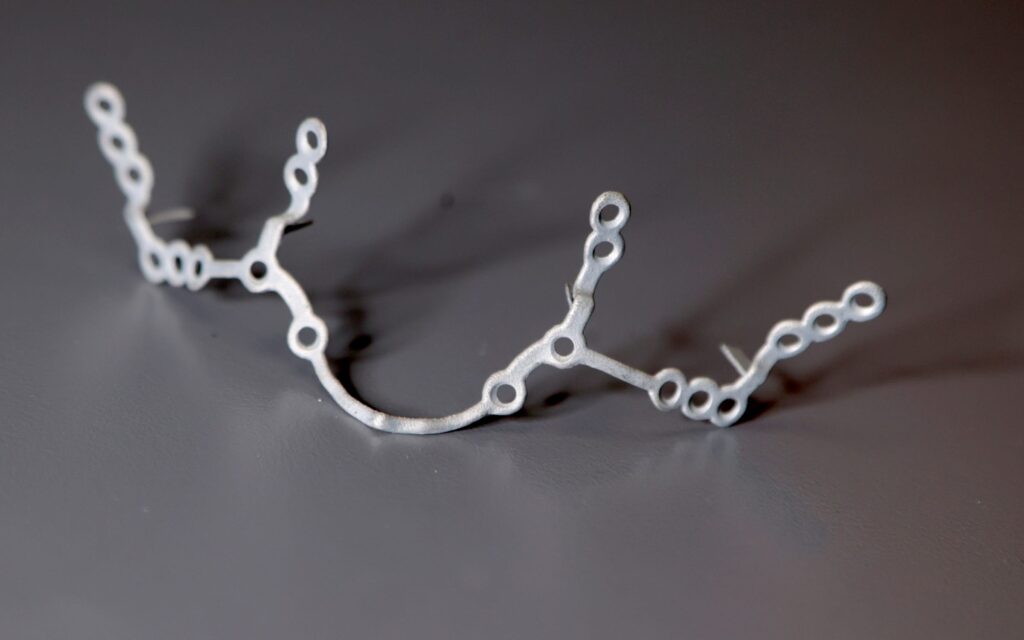

Medical Device Fabrication requires a delicate and precise process. It requires dozens of parts to be assembled in concert before they are delivered to the final assembly line. This requires original equipment manufacturers to find fabricators that have the capabilities to not only produce precision components, but they have to be able to adapt as well. From the design phase through fabrication the associates at IMH Products combine their skills and experience to make us a leading provider of parts for medical devices.

The array of processes that IMH Products can utilize allows us to stand out as a leader when it comes to producing components for medical devices. Our tool and die operators are experts at providing solutions to the unique challenges that these parts present. Medical devices require a range of custom metal components to function, including:

- Brackets

- Adapters

- Plates

- Precision welds

- Stands

IMH Products is where decades of experience meet cutting edge technology, which is the only way to guarantee quality and efficiency every time without compromising on price points or manufacturing time. There is no compromising on medical devices: they need to be perfectly accurate and durable enough to stand the test of time. That is why we are steadfast in our commitment to quality in every step of the process.

IMH Medical Device Fabrication Advantages

- Fabricated using some of the most advanced laser cutters in the Midwest.

- Price-effective while maintaining a high-level of precision.

- Made with strict adherence to ISO 9001 guideline.

- Created using the highest quality materials available.

When it comes to medical devices, it is necessary to be able to put trust in a manufacturer. With IMH, you will benefit from our decades of experience, investment in technology, and commitment to our customers.

If you are looking for a reliable fabricator for medical devices, start your conversation with us today to see how we can help.